Within our forestry division, we are commited to deliver comprehensive solutions for the wood processing industry. Our expertise spans from cutting-edge rotary debarkers, efficient screens, log ponds, waste conveyors, robust wood handling conveyors and high-capacity screw conveyors.

Designed to meet the demanding needs of OSB manufacturing facilities, our log pond system offers a comprehensive solution for log storage, preparation, and transportation.

Tailored to your facility’s specific requirements, our log pond systems can be configured to handle varying log sizes, species, and processing capacities. Modular components ensure flexibility and scalability.

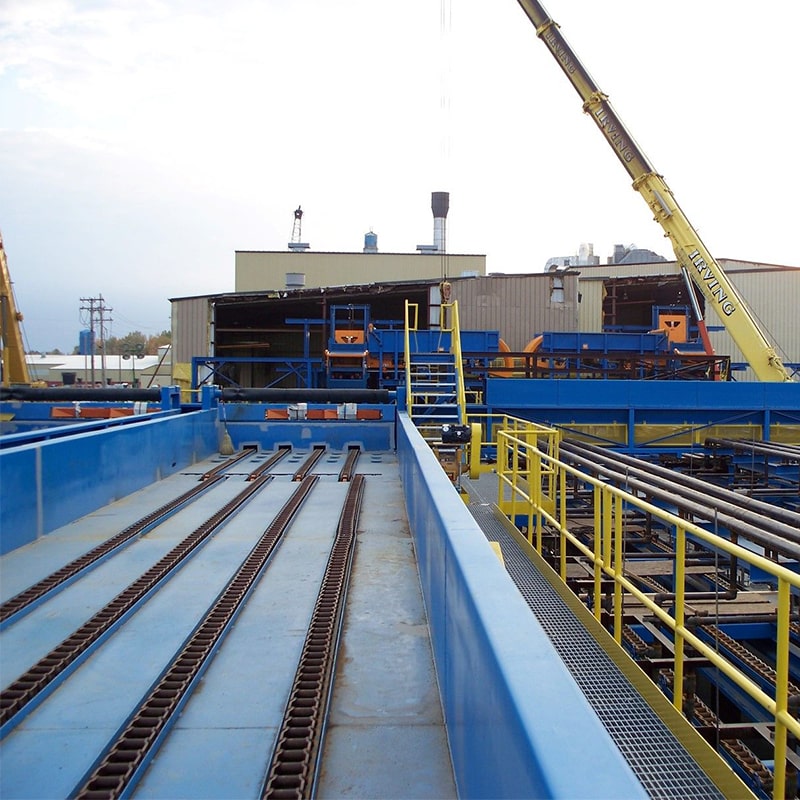

Forestry chain and belt conveyors are essential equipment in the forestry and timber processing industry, designed to streamline the handling and transportation of logs, lumber, bark and other forest products. These robust and efficient conveyor systems play a crucial role in improving productivity, reducing manual labor, and ensuring the safe and efficient movement of materials within a forestry operation.

Screw conveyors are versatile mechanical conveying systems used across various industries for the efficient and reliable movement of bulk materials, bark, strands, and other products. These devices consist of a rotating helical screw or auger enclosed in a trough or tube, enabling them to transport materials horizontally, vertically, or at inclined angles with precision and control.

Our customers affirm that our debarkers are designed to be more rugged than our competitors and require minimal maintenance, which ensures our products pay off quickly.

We can build your debarker with desired characteristics:

The stationary debarkers can come in multiple length between 2.5 m. (8 ft) and 9 m. (30ft), depending on your requirements. (CE approved).

Our debarking efficiency rate exceeds all of our customer’s expectations whether it be for soft or hard wood. Our results can reach up to 0.01% bark remaining per ton, even when debarking wood species like cedar or eucalyptus, characterized by their filamentous bark which causes a lot of problems in certain equipment. The results of our debarking tests have proven superior removal of bark and the high quality of our products.

With more than 40 years of experience in design, engineering, transport and debarking of logs, we can offer you all the transfer equipment:

Disc screens, also known as disc separators or rotary screens, are advanced mechanical sorting and screening equipment widely used for separating and sorting materials based on size, shape, and density. These versatile machines consist of a series of rotating discs or screens with precise spacing, allowing them to efficiently and accurately classify materials into different fractions.

Rotary screens, also known as rotary sieves or drum screens, are highly efficient mechanical devices used for the separation, classification, and screening of materials in industrial processes. These screens consist of a cylindrical drum with perforated plates or woven mesh surfaces, which rotate to sort and classify materials based on size, shape, and composition.

Log decks are essential components of log handling and processing systems in the forestry and lumber industry. These sturdy and specialized structures provide a designated area for sorting, staging, and temporarily storing logs before they undergo further processing. Log decks play a crucial role in optimizing workflow efficiency, reducing downtime, and ensuring the smooth transition of logs from the forest to the sawmill or other processing facilities.

Begin by completing our form. Our team is eager to assist you in finding the best solution for your needs.

Where Steel Meets Excellence – AJP: Your Trusted Partner in Custom Solutions for Over 30 Years.

All rights reserved © 2023 to date, Les Aciers J.P. Design by Graphix Design Graphique.